Optical Comparator (Profile Projector)

Measuring Microscopes (Tool Maker’s Microscopes)

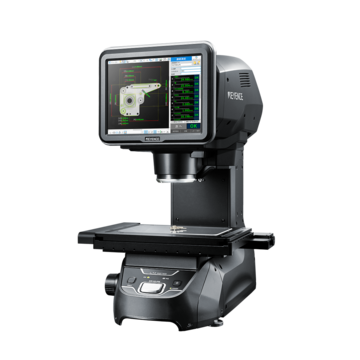

Explore KEYENCE's measuring microscope solutions. Achieve precise and detailed microscope measurements. Enhance your microscope measurement capabilities for quality control and analysis.

Overview of KEYENCE's Microscope Measurement Solutions

KEYENCE’s microscope measurement tool, the LM-1100 High Accuracy Image Dimension Measurement System, is an automated, efficient, and easy-to-use alternative to conventional measuring microscope tools. The name hardly does it justice. It has sub-micron accuracy, impressive speed, and non-contact height capabilities, and these features only scratch the surface of what the LM-1100 measuring microscope can do.

Benefits of Precise Microscope Measurement

Simultaneously Measure Parts

The LM-1100 measuring microscope tool can measure up to 600 of the same parts at the same time and up to 1000 dimensions on each of those parts. This efficient way to measure is ideal for large batches of parts that need inspection.

Consistency, Always

No matter who is operating the LM-1100 and regardless of operating style, the LM-1100 measuring microscope remains consistent with its measuring. The placement or positioning of the part does not affect the measurement results. The consistency of the LM-1100 is a revolutionary change compared to a classic optical comparator or tool maker's microscope.

Other measuring tools like an optical comparator and a tool maker's microscope rely heavily on metrology expertise combined with consistency and precision when in use. The LM-1100 requires no metrology background and no adjustments for part orientation regardless of how the operator places a part on the stage.

User Friendly

The LM-1100 is catered to the user's journey with the product. Here are a few ways that the LM-1100 measuring microscope achieves a user-friendly design:

- Only two steps for measurement – place the part and push the button. Compared to conventional machines with at least six steps.

- On-screen tutorials and illustrations that can be viewed at any time in the measuring process.

- Automated focus and lighting capabilities.

- Automatically records measurement data and generates inspection reports.

Key Features of Microscope Measurement Solutions

Telecentric Lens

The telecentric lens of the measuring microscope makes it possible to clearly see edges that previously could only be seen through magnification for easier and more-consistent high-accuracy measurements without any part image warping or distortion.

CMOS Sensor

The ultra-high-definition CMOS sensor makes it possible to get the maximum resolution performance from the lens. This monochrome 20-megapixel sensor enables seamless inspection and measurements.

Multi-Lighting System

The LM-1100 measurement microscope incorporates five built-in illumination settings for maximum efficiency and a not having a need to switch between multiple measurement tools or systems. The five different illuminations are:

- Telecentric Transparent Illumination

-

The telecentric illumination is a backlight for silhouette or shadow measurement for part profile measurement, or for transparent/translucent parts.

- Coaxial Illumination

-

Coaxial illumination is a 90-degree angle illumination for stronger contrast on certain applications like black and dark-colored material components that are challenging for conventional lighting.

- Four Division, Multi-Angle Illumination, Above

-

The above multi-angle illumination is illumination hitting the part diagonally from above. The switches between different lighting directions keep stability for low-contrast parts and assist with the measurement of tapered or blind features.

- Four Division, Multi-Angle Illumination Below

-

The below multi-angle illumination hits the part diagonally from below. This illumination optimizes high contrast for parts with height differences.

- Slit Ring Illumination

-

The slit ring illumination hits the part horizontally from either side, which is ideal for illuminating outer edge profiles.

FAQs About Measuring Microscopes

What Is a Measuring Microscope?

A measuring microscope is a magnification based measurement tool used to measure parts or samples. They can vary greatly in both capability, and automation, but often times, they are manual. Our LM-1100 is a new version of a measuring microscope, where the measurements are fully automated.

What Is the Value of Using a Measuring Microscope Over an Optical Comparator?

The value of using a measuring microscope over an optical comparator is the resolution of the image. With a higher resolution image, better accuracy can be guaranteed, so your measurement quality greatly improves. For the LM-1100, it has sub-micron level accuracy in high-precision mode, this is great for small parts with tight tolerances.

What Is the Accuracy and Repeatability of the Measuring Microscope?

The KEYENCE LM Series has an accuracy of +/-2 micron in wide field and +/-0.7 micron in high precision, while its repeatability is +/-0.1 micron. The accuracy of a measuring microscope is generally better than an optical comparator, but it varies based on model and capability.

Advantages of Non-Contact Height Measurement

Non-contact height is advantageous because it can be more accurate than probe measurements, more customizable since you can select exactly where to take the measurement, and less intrusive (no force on the part). There are plenty of parts that cannot be measured through contact methods due to possibility of warpage or deflection, such as catheters in the medical industry, so non-contact measurement is necessary.

Why Is This System Ideal for Parts With Tight Tolerances?

The KEYENCE LM Series is the ideal system to measure parts with tight tolerances as it has sub-micron accuracy and repeatability.

Related Downloads

Brochure for the LM-1100 Series High Accuracy Image Dimension Measurement System. Submicron accuracy part inspection with non-contact height measurement.

Brochure for the IM-8000 Series Image Dimension Measurement System. Accurately measure parts in seconds at the push of a button.

Brochure for the LM-X Series Multisensor Measurement System. Using optics, probes, and a multi-color laser to automatically measure all of your parts features.