CMM (Coordinate Measuring Machine)

CMM in Manufacturing and Fabrication

Coordinate measuring machines, also known as CMMs, are commonly used metrology machines for dimension and GD&T features. CMMs use a probe to collect coordinate points and calculate measurements with software.

For those in the manufacturing industry or fabrication industry, a coordinate measuring machine is an opportunity to streamline processes and final inspections.

How CMM Machines are Used in the Fabrication Industry

A CMM machine is typically used for in-process and final inspections in the fabrication industry.

In-process and final inspections include visual and dimensional processes. Although other tools like calipers, micrometers, and gauges can also be used for inspection, CMMs can do everything those tools can do, plus more. A CMM can successfully measure all fabrication measurements and also has the ability to evaluate GD&T features like flatness, squareness, parallelism, perpendicularity, and angularity. CMMs are automated and calculate this data instantly.

CMMs are also more accurate than other tools, making sure precision parts are truly as precise as claimed. These machines also measure complex shapes, including 3D elements, for any type of manufacturing needs.

Choosing the Right CMM for Fabrication Applications

Like most machines, CMMs have different models with pros and cons for various applications.

CMMs have three main categories: bridge/gantry, cantilever/horizontal, and portable. For manufacturing, the best CMM model is a portable CMM with easy-to-use, shop floor adaptable software.

Select the Proper Model

The proper CMM in manufacturing applications is a portable, handheld CMM. The reason? This model is the most versatile and accessible for inspections on the shop floor.

In-process and final inspections are necessary but time-consuming. Using a fixed position CMM in manufacturing means that production is stopped for transportation to an inspection area.

Unfortunately, while production is halted, it could still take days to wait for an available technician and machine for those inspections. With a portable and handheld CMM, you can cut down the total inspection time to just a couple of minutes, sparing the cost of lengthy downtime.

Portable, handheld CMMs are a great way to measure complex parts because the probe isn’t attached to anything, allowing for unlimited degrees of freedom. These CMMs are flexible to inspect curves, crevices, and holes because they’re maneuvered by a technician.

Select the Proper Software

The proper CMM software for the fabrication industry is one with a user-friendly interface, quick inspection time, 3D CAD comparison, and environmental controls.

The reality is that the manufacturing industry in general is facing a concerning lack of skilled technicians and an uptick in entry-level employees. Because of this, a new CMM must be easy to work with so it doesn’t add long training hours, and so it can be passed along between technicians. Likewise, a CMM with a quick inspection time is also key for ensuring that your CMM is helping reduce downtime.

Otherwise, two software additions to look for are 3D CAD comparison and environmental controls. 3D CAD comparison is when your CMM machine inspects a part and then compares it to its 3D CAD model. The CMM machine responds by revealing whether the part fits into the appropriate tolerances enlisted by the 3D CAD model. This software cuts down inspection time by automatically calculating the differences.

Lastly, software that is cohesive with vibrations and changing temperatures is vital for inspections on the shop floor. An environmental control software for these features can neutralize the measurements against the environment or reveal when the environment is too unstable for inspection. This is particularly helpful for shop-floor and portable CMMs, as they are exposed to many different environments every day.

Integrate the CMM into Manufacturing and Fabrication Process

Implementing coordinate measuring machines in fabrication and manufacturing will let you inspect your parts on the shop floor and will provide better accuracy than traditional hand tools.

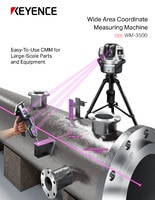

KEYENCE’s portable and handheld coordinate measuring machines, the WM and XM, are specialized for the fabrication and manufacturing industry. The XM and WM feature no-training-required software, fabrication measurement with the press of a button, 3D CAD model comparison, and temperature compensation. Our CMMs have transformed our customers' inspection processes, are you ready to transform your QC process?

Ready to learn more? Contact us today for a free demo.

Related Downloads

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM Series Measurement / Application Examples [Fabrication Application Examples]](/img/asset/AS_116822_L.jpg)

![WM Series Measurement / Application Examples [In-Machine Measurement Examples]](/img/asset/AS_116821_L.jpg)

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)