CMM (Coordinate Measuring Machine)

CMM for Shipbuilding

Coordinate measuring machines, also known as CMMs, are metrology machines for dimension and GD&T measurements. CMMs use a probe to collect coordinate points and calculate measurements with software. You can use them for a myriad of applications.

If you’re in the shipbuilding industry, a CMM provides an opportunity to optimize your inspection and measuring systems. They combine the use of a caliper, micrometer, gauges, and tape measure all into one machine. In this blog, we’ll discuss how to choose a CMM specifically for the shipbuilding industry.

How CMM Machines Are Used in the Shipbuilding Industry

Shipbuilding inspection and manufacturing is unique, as building occurs on the ship, manual tools are used, and inspections happen when components are assembled.

Because of these characteristics, shipbuilding inspection and metrology are heavily focused on obtaining GD&T data with specialized and portable tools.

Using a coordinate measuring machine for shipbuilding minimizes your collection of tools while ensuring easy transportability and ease of GD&T measuring. CMMs measure flatness, angles, depth, thickness, parallelism, dimensions, and more, so there’s no need to use one tool for each type of measurement. Portable CMMs are transportable around the ship, measure complex shapes like propellers and wires, and reach into holes to measure depth.

Choosing the Right CMM for Shipbuilding Applications

Like most machines, CMMs have different models with pros and cons for various applications.

CMMs have three main categories: bridge/gantry, cantilever/horizontal, and arm/portable. For the shipbuilding industry, the best CMM model to use is a portable CMM with adaptable software. Let's discuss why.

Select the Proper Model

All CMM models use a probe to measure dimensions and GD&T data, but they each have different setups.

Portable arm CMMs are flexible in comparison to the other CMM categories. The probe is maneuvered by a technician, and there doesn’t have to be a stage for a component or part to rest on. Portable CMMs are the best for shipbuilding inspection because you can bring the CMM to the vessel.

Bridge/gantry and cantilever/horizontal CMMs use a stage and a probe manipulated by the CMM. The stage is either on the floor or raised and attached to the rest of the machine. These models are usually stationary and require bringing the part to the CMM.

Although bridge, gantry, cantilever, and horizontal CMMs are frequented in other industries, none of them are the ideal coordinate measuring machines for shipbuilding. These models are difficult to transport because of their heavy and stationary nature. In addition, since most shipbuilding inspection occurs after assembly within the vessel, it would be physically impossible to inspect with these models.

Select the Proper Software

CMMs usually include software that makes the measuring or inspecting process more efficient. If you work in the shipbuilding industry, that means you’re measuring against a plethora of outside variables: temperature, humidity, light, technicians, and vibrations.

Software that neutralizes the environment and is adaptable between technicians is ideal for your CMM for shipbuilding. Neutralizing software includes temperature or vibration compensation. Adaptable software is software that prevents human errors and is intuitive to use regardless of the technician using it.

Integrate a CMM into Your Ship Manufacturing Processes

Implementing a coordinate measuring machine for shipbuilding will automate your shipbuilding inspection and replace your collection of tools with one that does it all.

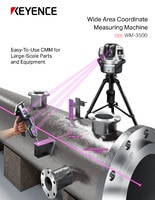

KEYENCE’s portable and handheld coordinate measuring machines are specialized for shipbuilding, featuring no-training-required software, real-time measurement response, and temperature compensation. Our CMMs transport between technicians in a rolling case and remain consistent with measurements no matter who is using it.

Stop worrying about transferring measurement data or tools. We’re ready to optimize your shipbuilding processes. Contact us today to learn more.

Related Downloads

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM Series Measurement / Application Examples [Fabrication Application Examples]](/img/asset/AS_116822_L.jpg)

![WM Series Measurement / Application Examples [In-Machine Measurement Examples]](/img/asset/AS_116821_L.jpg)

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)